Geothermal systems, otherwise known as geo-exchange or earth energy systems, provide consistent heating and cooling year round, by tapping into the earth’s nearly constant temperatures which are found just below the frost line.

Geothermal systems have only been around in Canada for about 60 years. Credit goes in large part to Professor Frank Hopper of the University of Toronto who first brought this system to the main stage.

In 2000 there were approximately 1,000 geothermal systems installed across Canada. This number steadily increased annually to nearly 6,000 systems installed in 2006 and 16,000 new systems in 2009.

Geothermal Systems are incredible efficient. Their efficiencies are known as “coefficient of performance” (COP). That means for every unit of energy used to power the system, three to five units are supplied as heat, an efficiency rating of 300-500%.

To put this in perspective, the COP for a traditional electric systems is 1 to 1, or 1 to 1.5 for natural gas systems.

There is also the strong environmental or green argument. Geothermal systems virtually eliminate the combustion of fossil fuels on site which dramatically reduces the damage associated with emission of greenhouse gases and resulting damage to the environment.

A key consideration is the reduction of reliance to increased energy costs, related to the volatile fossil fuel commodity prices.

Geothermal systems are suited for virtually any application, whether it be traditional heating and cooling, in-floor heating, melting systems, domestic hot water and even heating of swimming pools or chilling of hockey pads.

Gone are the days of noisy condensing units, chimney stacks and other unattractive equipment that are exposed to the elements. Geothermal systems are quiet, compact and discrete.

While each site is unique, most geothermal systems cost between $3,000-5,000 per 10,000 Btu (1 ton), which is enough energy to condition a 1,000 sq. ft. condo.

So how does it work?

There are basically two ways to move this energy from the ground, and into the building, an open loop (otherwise known as a well-water system) or a closed loop.

A closed loop system consists of high-density polyethylene (HDPE) pipe, which can last upwards of 50 years. Most systems run a mixture of ethanol and water which is circulated continuously through the loop and heat pump, transferring heat from or to the soil respectively, as heating or air conditioning is needed.

Closed loop systems are completed sealed, so fluid never comes in contact with the soil.

In an open loop system, ground water is drawn from a well or open pond, through the heat pump, and then pumped back into a return well or pond. New water is always being pumped through the system when it’s in operation.

The closed loop system can be installed in three basic configurations, vertical, horizontal and lake. Site conditions including future plans will determine the loop type most suitable.

A horizontal loop system is buried horizontally at a depth between 1.5 and 3 m. The number of trenches and the quantity of loops per trench is calculated based on the anticipated heating and cooling loads of your site, and will also take into consideration the type of soil, existing conditions of that soil such as moisture and the climate which the site is located.

Sites that have available open table land, and will not require future redevelopment of this land benefit from this type of installation.

A vertical loop system is inserted into boreholes drilled that are approximately 10-15 cm in diameter, and based on existing site conditions, can be upwards of 150 m deep. The loop is then inserted in to each borehole and grouted to ensure solid contact with the soil.

The grouting process is accomplished by inserting a pipe to the bottom of the borehole, and solely retracted as the grout material is added, thus eliminating air pockets which may affect the efficiency of the system.

A large benefit of this style of system is that it can be installed in a much smaller footprint than its counterpart, however, can be four times as expensive to install.

Ground water temperature is very constant, ranging between 5 and 12 celcius.

This water is pumped up, run past a heat exchanger, and then returned.

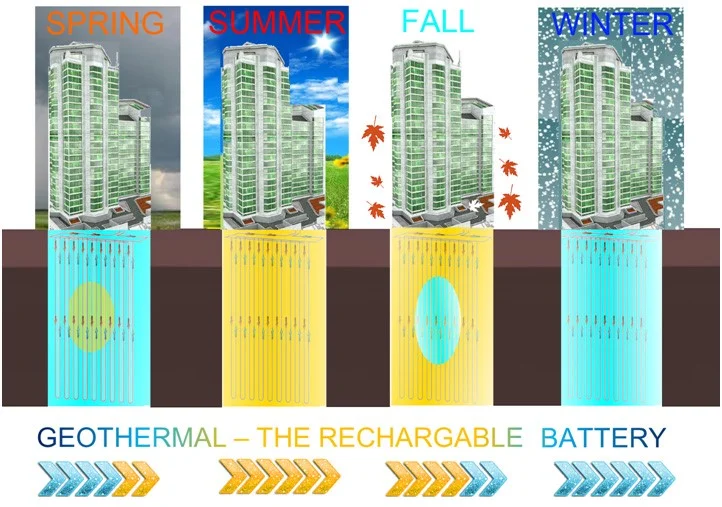

In the winter, the fluid absorbs this stored heat and carries it indoors. The indoor heat exchanger compresses the heat to a higher temperature and distributes it through the site. Typical energy savings between 30-70% are achieved over traditional heating systems.

In the summer, the system works in reverse by pull heat from the building and carries it through the earth loop, where it deposits the heat into the cooler earth. Savings are not as robust, with typical reductions in the range of 20-50%.

There are three main components of a Geothermal System, the heat-pump unit, the liquid heat-exchange medium, and the heating/cooling delivery system (duct and/or hydronic).

Mechanical equipment lasts longer if it is running continuously, which doesn’t mean 100%, as variable speed motors not only extend the life of the system, but assist in lowering hydro costs. Additionally, sizing of the system, including the pumps is paramount. Bigger is not better.

The Canadian GeoExchange Coalition (GCG) has been training and accrediting industry professionals since 2007. If your condominium corporation is entertaining to convert the existing system to GeoThermal, or you have an existing system, ensure your contractor is GCG accredited by visiting www.geoexchange.ca.

For more information related to Geothermal Systems, installation, maintenance, payback periods and questions in general, feel free to contact Central Erin Property Management